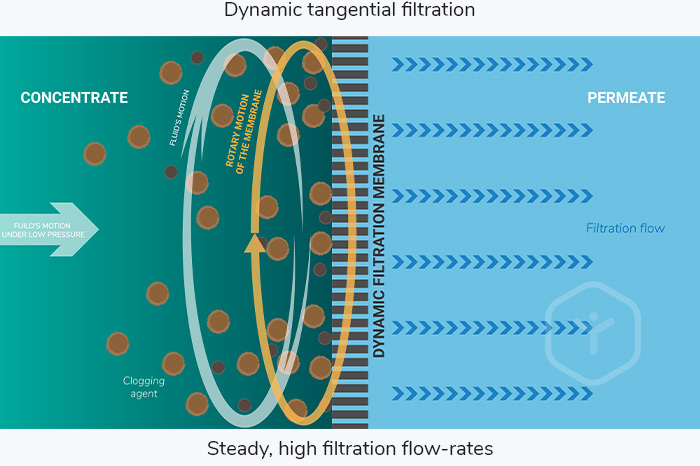

Dynamic tangential filtration

Depending upon the specificity of your industrial water and effluents, we can offer a dynamic, tangential filtration system.

This is an effective system for achieving high,

steady filtration flow-rates.

The choice of using dynamic, tangential filtration has to be made depending upon the effluents to be treated and the expected results. A preliminary study is always needed.

How does it work?

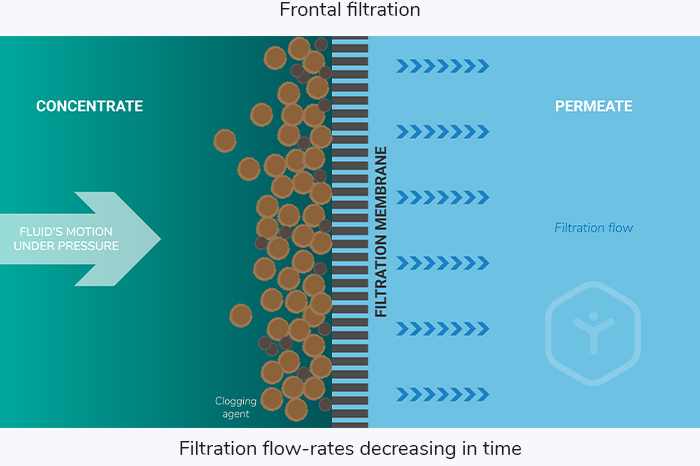

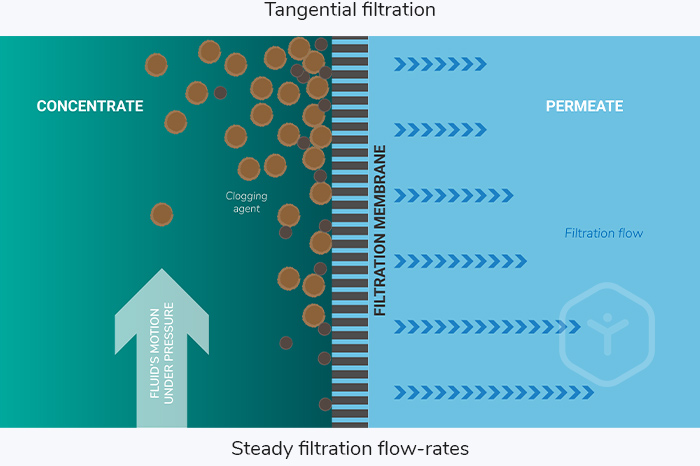

It is based on the principle of generating a rotational movement between the membrane and the casing, which would generate significant shear rates near the membrane surface. This limits the growth and compression of the layer of clogging agent which forms in that area, so the equipment can work at low trans-membrane pressure.

Its advantages

Compared with traditional tangential filtration, results remain optimum over time and this still little-known technique has many advantages:

Significant resistance to clogging

It treats heavily loaded liquids

(several tens of g/l of CODs/SSs)

Excellent REUSE rate

(95% of the water can be reused)

Low energy consumption

Sustainable reliability

Very compact

Its applications

Depending upon the specificity of your needs, we can use dynamic, tangential filtration with different types of membranes for efficiently reaching your goals. It can be used with::

- Micro-filtration membranes for abating bacteria, suspended solids, colloids and certain emulsions;

- Ultrafiltration membranes for the full abatement of suspended solids, viruses, bacteria, colloids and nano-particles or large organic molecules (>10 nm);

- Nano-filtration membranes (organic molecules (BOD/COD) and dissolved solids);

- Reverse osmosis membranes (dissolved salts (NaCl) and also larger compounds like traces of oil, metals or organic molecules);

Are you interested in this technology?

Contact our Water and Effluent Treatment Manager directly: